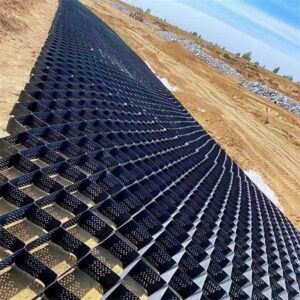

Advanced biaxial geogrid technology delivering superior soil stabilization and base reinforcement for roadway construction. Engineered with time-tested design principles to enhance pavement performance and reduce construction costs.

Our Professional Biaxial Geogrid systems represent cutting-edge geosynthetic engineering, offering improved roadway solutions through proven design principles. These high-performance geogrids provide dual functionality: soil stabilization and base reinforcement in a single, integrated solution.

Manufactured from premium polypropylene using advanced punched and drawn manufacturing processes, these biaxial geogrids deliver exceptional tensile strength and junction efficiency. The unique mechanical interlock system ensures optimal load transfer and aggregate confinement.

| Property | Unit | Standard Grade | Heavy Duty Grade |

|---|---|---|---|

| Tensile Strength @ 2% Strain | lb/ft (kN/m) | 280 (4.1) MD / 450 (6.6) XMD | 410 (6.0) MD / 620 (9.0) XMD |

| Tensile Strength @ 5% Strain | lb/ft (kN/m) | 580 (8.5) MD / 920 (13.4) XMD | 810 (11.8) MD / 1,340 (19.6) XMD |

| Ultimate Tensile Strength | lb/ft (kN/m) | 850 (12.4) MD / 1,300 (19.0) XMD | 1,310 (19.2) MD / 1,970 (28.8) XMD |

| Junction Efficiency | % | 93 | 93 |

| Aperture Stability | m-N/deg | 0.32 | 0.65 |

Superior performance for primary and secondary road construction. Reduces aggregate thickness requirements and enhances pavement life.

Effective stabilization of soft roads through mechanical aggregate interlock. Reduces construction costs and improves long-term performance.

Heavy-duty applications requiring maximum load distribution and stability. Suitable for high-traffic aviation infrastructure.

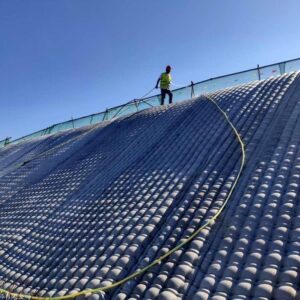

MSE wall construction and slope reinforcement applications. Provides mechanical stabilization for challenging terrain conditions.

Enables construction over challenging subgrade conditions. Deep undercutting or chemical stabilization alternatives.

Heavy haul roads and access routes for renewable energy infrastructure. Supports extreme load requirements for construction equipment.

Our Professional Biaxial Geogrid systems deliver proven performance based on decades of successful field applications. The unique combination of high tensile strength, superior junction efficiency, and positive mechanical interlock provides unmatched soil reinforcement and base stabilization capabilities.

Ensure proper preparation and compaction of subgrade surface. Remove any sharp objects or debris that could damage the geogrid.

Position geogrid with machine direction aligned with primary traffic direction. Maintain proper overlap at joins and anchor securely.

Place and spread aggregate carefully to avoid damage. Use appropriate lift thickness and compaction methods for optimal performance.

Conduct regular inspections during installation. Verify proper compaction levels and geogrid integrity throughout construction.

Professional Grade Straw Coconut Erosion Control Blanke […]

View Details