Advanced three-dimensional cellular confinement technology engineered from high-density polyethylene (HDPE) for superior soil stabilization, slope protection, and load distribution across challenging terrain applications.

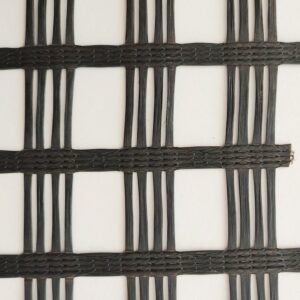

Our Geocell Cellular Confinement System (CCS) represents a breakthrough in geosynthetic engineering. This innovative three-dimensional expandable panel system is manufactured from premium High Density Polyethylene (HDPE) strips, ultrasonically bonded to create an exceptionally strong honeycomb configuration.

When infilled with compacted soil, aggregate, or other materials, the geocell creates a composite structure with dramatically enhanced mechanical and geotechnical properties. The three-dimensional confinement significantly reduces lateral soil movement while distributing loads over a wider area.

Prepare subgrade surface and install geotextile if required. Ensure proper drainage and compaction of foundation layer.

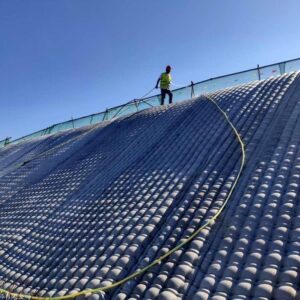

Unfold geocell panels and expand to full dimensions. Connect panels using integrated fastening system to create continuous coverage.

Secure geocell panels using appropriate anchoring system. Install stakes or pins according to project specifications and soil conditions.

Fill cells with specified material (soil, aggregate, concrete). Compact using appropriate equipment to achieve required density.

Effective protection against downward migration of slope materials. Suitable for slopes up to 60 degrees with various infill options.

Enhanced hydraulic performance for high-velocity flow events. Increased shear resistance through aggregate confinement.

Road and pavement applications with increased resistance to lateral displacement. Reduces rutting and extends pavement life.

Retaining wall applications with enhanced stability. Suitable for various infill materials and wall heights.

Ideal protection for impervious liners. Can be installed without stakes and filled with various protective materials.

Cost-effective alternative to traditional riprap. Allows use of smaller, locally available aggregate materials.

Our Geocell Cellular Confinement Systems represent decades of geosynthetic engineering advancement, providing proven solutions for the most challenging soil stabilization, slope protection, and load support applications. The three-dimensional cellular structure creates a composite material that dramatically outperforms traditional methods.

Professional Grade Straw Coconut Erosion Control Blanke […]

View Details