Advanced permeable concrete lining solutions with integrated filtering points for superior erosion protection. Our Filter Point systems provide stable, durable protection for channels, ditches, waterways, and marine infrastructure with controlled drainage and reduced hydraulic uplift.

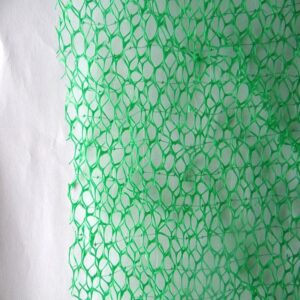

Filter Point Linings feature strategically placed filtering points (drains) that provide erosion-resistant, permeable concrete lining for a wide range of water management applications. The distinctive cobbled surface design offers high hydraulic friction to achieve lower flow velocities and reduce wave run-up.

These systems excel where traditional stone riprap or conventional slope paving fall short, offering superior stability through hydrostatic pressure relief, reduced hydraulic uplift, and excellent conformity to soil contours during installation.

| Model | Average Thickness | Mass Per Unit Area | Filter Point Spacing | Concrete Coverage |

|---|---|---|---|---|

| FP220 | 2.2 inches (56 mm) | 25 lb/ft² (121 kg/m²) | 5.0 inches (127 mm) | 136 ft³/yd² (36 m³/m²) |

| FP400 | 4.0 inches (102 mm) | 45 lb/ft² (220 kg/m²) | 8.0 inches (203 mm) | 75 ft³/yd² (9.1 m³/m²) |

| FP600 | 6.0 inches (152 mm) | 68 lb/ft² (330 kg/m²) | 10.0 inches (254 mm) | 50 ft³/yd² (6.1 m³/m²) |

| FP800 | 8.0 inches (203 mm) | 90 lb/ft² (440 kg/m²) | 12.0 inches (305 mm) | 38 ft³/yd² (4.6 m³/m²) |

| FP1000 | 10.0 inches (254 mm) | 113 lb/ft² (550 kg/m²) | 14.0 inches (356 mm) | 30 ft³/yd² (3.6 m³/m²) |

| FP1200 | 12.0 inches (305 mm) | 135 lb/ft² (661 kg/m²) | 16.0 inches (406 mm) | 25 ft³/yd² (3.0 m³/m²) |

Note: Values shown are typical and will vary with weight of concrete and field conditions. All specifications are based on standard testing methods and controlled installation procedures.

Proportioned mixture of Portland cement, fine aggregate (sand), and water with proper consistency for pumping applications.

Efflux time of 9-12 seconds through 0.75 inch (19 mm) orifice per ASTM C 939.

Minimum 2,000 lb/in² (13.8 MPa) at 28 days per ASTM C 31 and C 39.

Erosion-resistant lining for irrigation ditches, drainage channels, and conveyance systems requiring hydraulic efficiency with reduced flow velocities.

Bank protection and bed stabilization for natural waterways, providing erosion control while maintaining environmental compatibility.

Slope protection for water storage facilities, retention ponds, and reservoir embankments with hydrostatic pressure management.

Protected port areas, harbor facilities, and marina applications where wave run-up reduction and drainage are critical.

Long-distance water conveyance systems requiring durable, low-maintenance lining with predictable hydraulic performance.

Shoreline stabilization and erosion control for natural and constructed lakes with effective wave energy dissipation.

System must withstand hydraulic loadings including velocity, depth, duration, shear stress, pressure, and frequency of immersion for design discharges. Minimum factor of safety: 1.5

System must withstand depth, duration, wave type, wave height and period, and pressure distribution for design wave conditions. Minimum factor of safety: 1.5

Surface preparation to specified grades and dimensions, removal of obstructions, and compacted base as required.

Installation of filter fabric on prepared surface, providing proper drainage and separation.

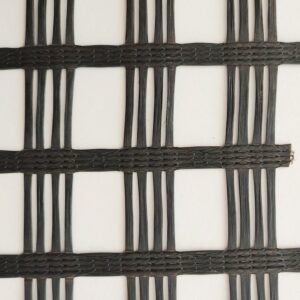

Positioning and anchoring of double-layer fabric forms with proper seaming and connection methods.

Pumping of fine aggregate concrete to specified thickness while avoiding excessive pressure and cold joints.

Select appropriate Filter Point mattress model based on hydraulic conditions, shear stress requirements, and site-specific factors. Consider flow velocities, wave heights, soil conditions, and long-term stability requirements.

FP220-FP400 for low-velocity channels, drainage ditches, and protected areas with minimal hydraulic stress.

FP600-FP800 for moderate flow conditions, canal linings, and reservoir slopes with intermediate protection needs.

FP1000-FP1200 for high-velocity channels, wave action areas, and critical infrastructure requiring maximum protection.