Advanced engineered textile dewatering solutions for sludge management and sediment containment. Our geotube systems provide simple, cost-effective dewatering technology for projects of all sizes, from municipal wastewater treatment to industrial applications.

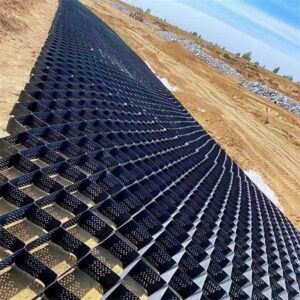

Geotube dewatering systems, also known as geobags, are engineered textile containers designed for efficient sludge dewatering and sediment management. These systems use advanced filtration technology combined with polymer treatment to separate solids from liquids effectively.

With no mechanical components like belts or gears, geotube systems offer a simple yet highly effective solution for dewatering high moisture content sludge and sediment across various industries.

Up to 85-90% BOD reduction and significant volume reduction

Custom fabrication to meet specific project volume requirements

Roll-off container mounting for portable applications

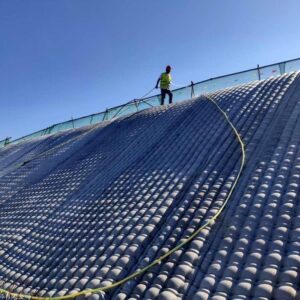

Engineered textiles withstand high pumping pressures

Geotube containers are delivered to site and positioned according to project requirements, with proper drainage systems in place.

Sludge is treated with specialized polymers to optimize the separation of solids and liquids during the dewatering process.

Treated sludge is pumped into the geotube containers through reinforced inlet connections designed to handle high flow rates.

Clear effluent water drains through the engineered textile while solids are retained within the container.

Complete containers can be transported to approved landfill facilities

Dewatered solids can be removed and used for land application where appropriate

Efficient dewatering of municipal sludge with significant volume reduction and BOD removal for wastewater treatment plants.

Tailings management, coal sludge dewatering, and mineral processing waste containment for mining operations.

Pulp and paper industry lagoon cleanout, power utility waste management, and light industrial sludge dewatering.

Dairy industry waste, piggery effluent, abattoir waste management, and other agricultural waste dewatering applications.

Sediment containment and dewatering for dredging projects, harbor maintenance, and marine environmental remediation.

Fish farm waste management, aquaculture effluent treatment, and pond sediment dewatering for sustainable aquaculture operations.

Bulk Bag Size: Compact units for small volume applications

Standard Small: 7.6m × 4.4m units optimal for medium projects

Stock Availability: Ready for immediate deployment

Standard Sizes: Various predetermined dimensions available

Quick Deployment: Minimal lead time for standard configurations

Versatile Applications: Suitable for most industrial applications

Custom Fabrication: Engineered to specific project requirements

High Volume: Designed for major industrial and municipal projects

Project Support: Technical consultation and design assistance

Geotube dewatering technology represents one of the most versatile and effective solutions available for sludge management. The simplicity of operation, combined with proven engineering and cost-effectiveness, makes it the preferred choice for dewatering projects ranging from small municipal applications to large-scale industrial operations.

Professional Grade Straw Coconut Erosion Control Blanke […]

View Details